Informational blogs

Villainy Ink Phase II: Refined Enamel Washes & Effects for...

Villainy Ink Phase II refines enamel washes and effects for grimdark—richer pigment, faster dry, and airbrush-friendly tones for dust, rust, and believable grime.

Body Paint & Makeup: Face Painting Ideas for Vivid and...

Body paint and makeup have transcended simple decoration; they've become powerful tools for self-expression, artistic creation, and transformation. Whether you're gearing up for Halloween, preparing for a cosplay convention, or simply looking to unleash your inner artist, understanding the nuances of body paint is essential. From choosing the right type of paint to mastering application techniques, this guide will help you create vivid and smudge-proof designs that truly stand out. Let's dive into the colorful world of face and body art!

Types of Airbrushes: Things to Know When Buying Your First...

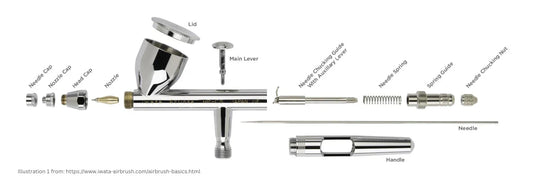

An airbrush is a precision tool that uses compressed air to spray a fine, even layer of paint. This technique is essential for creating the smooth finishes, perfect transitions, and fine details that are difficult to achieve with traditional brushes. While they were once primarily used in the automotive art world, airbrushes are now indispensable tools for miniature painters, illustrators, makeup artists, and more.

However, the wide variety of airbrushes can be confusing for a beginner. With different control types, feed systems, and mixing methods, choosing the right one can feel complicated. This guide will walk you through the key differences between airbrushes and help you choose the best one for your needs. We'll cover everything from double-action systems to gravity-feed models and answer your most common questions so you can start airbrushing with confidence.

Complete Guide to Getting Started in Miniature Painting

If you’ve ever seen a display case full of perfectly painted Warhammer armies or an impressive Gundam with every detail highlighted and thought, “I want to do that, but I don’t know where to start,” welcome, because this guide’s for you. Whether your goal is to have a complete army ready for the gaming table, to build an impressive Gundam model collection, or simply relax painting figures, you’ll find everything you need to start right here.

Acrylic, Lacquer, or Enamel? The Ultimate Guide to Model Paints

Choosing the right paint is one of the biggest challenges in scale modeling, whether you’re a beginner or an experienced modeler aiming for a flawless finish. Today, there are more options than ever: acrylics, enamels, lacquers, oils… and to make things even more confusing, “lacquer-type acrylics” that behave like lacquer without actually being lacquer.

So many options lead to lots of questions: What are the real differences? Which one should you use for a base coat? Which varnish should you apply before decals or washes? What happens if your colors come from different paint families? Is it safe to spray lacquer over acrylic?

Read Your Airbrush: Unlocking the Secrets of Your Spray Pattern...

Learning to read your airbrush's spray pattern is, without a doubt, one of the most useful skills you'll ever pick up in the world of airbrushing. Think of it as your airbrush's secret language – and once you understand it, you'll be able to tell exactly what your tool needs to give you the perfect finish, every single time. It's like having a direct line to your airbrush's soul, and trust me, it’s going to save you a ton of headaches and wasted paint.