Paints for shoe painting

Equipment and tools

-

Vendor:Createx

Vendor:CreatexIllustration Flexible Adhesion Promoter

Regular price From $3.33 USDRegular price -

Vendor:Createx

Vendor:CreatexIllustration Colors Sepia 5063

Regular price From $3.97 USDRegular price -

Vendor:Createx

Vendor:CreatexCreatex Wicked Colors Hot Rod Sparkle Blue W423

Regular price From $7.93 USDRegular price -

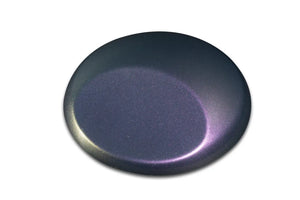

Vendor:Createx

Vendor:CreatexCreatex Wicked Pearl Purple W311

Regular price From $5.50 USDRegular price -

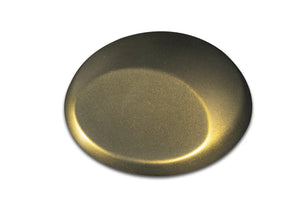

Vendor:Createx

Vendor:CreatexWicked Golden Yellow W011

Regular price From $5.30 USDRegular price -

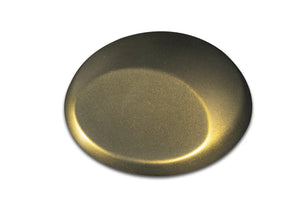

Vendor:Createx

Vendor:CreatexWicked Colors Metallic Elegance W367

Regular price From $5.50 USDRegular price -

Vendor:Createx

Vendor:CreatexWicked Colors Detail Burnt Sienna W074

Regular price From $5.30 USDRegular price -

Vendor:Createx

Vendor:CreatexCreatex Wicked Colors Hot Rod Sparkle Spectrum W421

Regular price From $7.93 USDRegular price -

Vendor:Createx

Vendor:CreatexCreatex Wicked Colors Cosmic Sparkle Silver W440

Regular price From $7.54 USDRegular price -

Vendor:Createx

Vendor:CreatexIllustration Colors Black 5051

Regular price From $3.97 USDRegular price -

Vendor:Createx

Vendor:CreatexCreatex Wicked High Gloss White W017

Regular price From $6.20 USDRegular price -

Vendor:Createx

Vendor:CreatexCreatex Wicked Pearl Plum W307

Regular price From $5.50 USDRegular price -

Vendor:Createx

Vendor:CreatexWicked Colors Detail Black Magenta W075

Regular price From $5.30 USDRegular price -

Vendor:Createx

Vendor:CreatexWicked Colors Aluminum Coarse W356

Regular price From $5.50 USDRegular price -

Vendor:Createx

Vendor:CreatexWicked Opaque Flat Black W098

Regular price From $5.30 USDRegular price -

Vendor:Createx

Vendor:CreatexCreatex Wicked Colors Hot Rod Sparkle Purple W426

Regular price From $7.93 USDRegular price -

Vendor:Createx

Vendor:CreatexWicked UV Glow Base W210

Regular price From $5.30 USDRegular price -

Vendor:Createx

Vendor:CreatexWicked Colors Metallic White Coarse W361

Regular price From $5.50 USDRegular price -

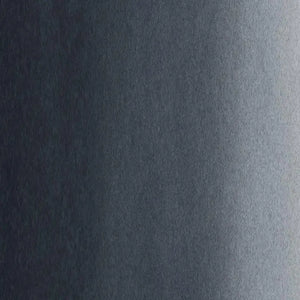

Vendor:Createx

Vendor:CreatexIllustration Paynes Grey 5066

Regular price From $3.97 USDRegular price -

Vendor:Createx

Vendor:CreatexCreatex Wicked Colors Hi-Lite Blue W404

Regular price From $5.56 USDRegular price -

Vendor:Createx

Vendor:CreatexWicked Blue W007

Regular price From $5.30 USDRegular price -

Vendor:Createx

Vendor:CreatexCreatex Wicked Colors Cosmic Sparkle Blue W444

Regular price From $7.54 USDRegular price -

Vendor:Createx

Vendor:CreatexWicked Fluorescent Sunburst W025

Regular price From $5.30 USDRegular price -

Vendor:Createx

Vendor:CreatexWicked Orange W004

Regular price From $5.30 USDRegular price -

Vendor:Createx

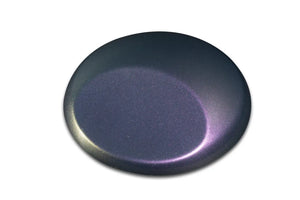

Vendor:CreatexCreatex Wicked Colors Flair Tint Teal-Purple W451

Regular price From $8.12 USDRegular price -

Vendor:Createx

Vendor:CreatexWicked Colors Metallic Light Brown W370

Regular price From $5.50 USDRegular price -

Vendor:Createx

Vendor:CreatexCreatex Wicked Colors Hi-Lite Gold W400

Regular price From $5.56 USDRegular price -

Vendor:Createx

Vendor:CreatexCreatex Wicked Colors Flair Blue/Violet W454

Regular price From $9.49 USDRegular price -

Vendor:Createx

Vendor:CreatexCreatex Wicked Colors Hot Rod Sparkle Red W425

Regular price From $7.93 USDRegular price -

Vendor:Createx

Vendor:CreatexWicked Opaque Brown Oxide W092

Regular price From $5.30 USDRegular price -

Vendor:Createx

Vendor:CreatexWicked Colors Metallic Rose W372

Regular price From $5.50 USDRegular price -

Vendor:Createx

Vendor:CreatexWicked Colors Metallic Charcoal-Viola W368

Regular price From $5.50 USDRegular price -

Vendor:Createx

Vendor:CreatexWicked Brown W010

Regular price From $5.30 USDRegular price -

Vendor:Createx

Vendor:CreatexCreatex Wicked 2oz Opaque Primary Set W131

Regular price $31.00 USDRegular price -

Vendor:Createx

Vendor:CreatexWicked Colors Detail Paynes Grey W071

Regular price From $5.30 USDRegular price -

Vendor:Createx

Vendor:CreatexW133-02 Createx Wicked Colors Metallic Galaxy Set 12 x 60ml

Regular price $65.00 USDRegular price

Custom shoe supplies for painting and airbrushing custom sneakers.

Custom shoe supplies for customizing shoes with airbrush techniques has become increasingly popular, allowing artists and hobbyists to create unique, personalized footwear. Whether you're a beginner or an experienced artist, having the right supplies is crucial for achieving professional and durable results. This guide will walk you through the essential supplies needed for airbrushing custom shoes.

1. Airbrush and Compressor

- Airbrush: A high-quality airbrush is the cornerstone of your custom shoe painting kit. Gravity feed, dual-action airbrushes are preferred for their precision and control. Models like the Iwata Eclipse HP-CS or the Harder & Steenbeck Evolution are excellent choices, offering fine atomization and smooth paint flow.

- Compressor: A reliable air compressor ensures consistent airflow, which is essential for even paint application. Look for a compressor with adjustable pressure settings, like the Iwata Smart Jet Pro, to accommodate different paint types and techniques.

2. Paints

- Acrylic Paints: Water-based acrylic paints are ideal for custom shoe projects due to their flexibility, durability, and ease of use. Brands like Angelus and Jacquard offer paints specifically formulated for leather and fabric, ensuring vibrant colors that won’t crack or peel.

- Paint Reducers: Thinning your paints with the appropriate reducer ensures smooth flow through the airbrush and prevents clogging. Angelus 2-Thin and Createx 4011 Reducer are popular options for achieving the right consistency.

3. Preparation Supplies

- Cleaners and Degreasers: Proper surface preparation is crucial for paint adhesion. Use a cleaner like Angelus Leather Prep & Deglazer to remove any oils, waxes, and finishes from the shoes before painting.

- Sandpaper: Lightly sanding the surface with fine-grit sandpaper (around 400-600 grit) can help the paint adhere better, especially on glossy surfaces.

- Masking Tape and Stencils: High-quality masking tape protects areas of the shoe you don’t want to paint, and stencils allow for intricate designs and patterns. Look for tape that is easy to remove without leaving residue, such as 3M Scotch Blue Painter's Tape.

4. Finishing Supplies

- Sealants: Applying a protective sealant is essential to ensure the longevity of your custom design. Angelus Acrylic Finisher and Liquitex Acrylic Varnish are excellent options that provide a durable, water-resistant finish.

- Heat Gun: A heat gun helps to set the paint, increasing its durability. Be cautious with the temperature to avoid damaging the material.

5. Additional Tools and Accessories

- Airbrush Cleaning Kit: Regular maintenance of your airbrush is essential for optimal performance. A cleaning kit typically includes brushes, needles, and cleaning solutions to keep your airbrush in top condition.

- Palette and Mixing Cups: For mixing and thinning paints, use a palette and small mixing cups. This allows for precise control over paint colors and consistency.

- Protective Gear: Safety should always be a priority. Wear a mask or respirator to protect yourself from inhaling fumes and particles, and use gloves to keep your hands clean.

Step-by-Step Guide to Airbrushing Custom Shoes

- Prepare the Shoes: Clean the shoes thoroughly with a cleaner/degreaser to remove any oils and waxes. Lightly sand the surface if necessary.

- Plan Your Design: Sketch your design and decide on the color scheme. Use masking tape and stencils to outline your design on the shoes.

- Mix the Paint: Thin your acrylic paints with the appropriate reducer to achieve the desired consistency. Test the paint flow on a piece of scrap material.

- Apply the Base Coat: Using your airbrush, apply a thin, even base coat. Allow it to dry completely before applying additional layers.

- Add Details: Layer different colors and use stencils to add intricate details. Take your time to build up the design gradually.

- Seal the Design: Once the paint is fully dry, apply a protective sealant to ensure the design is durable and water-resistant.

- Cure the Paint: Use a heat gun to gently cure the paint, setting it into the material for added durability.

Conclusion

Customizing shoes with airbrush techniques is a rewarding and creative process that allows you to express your unique style. By investing in the right supplies and following proper techniques, you can create stunning, one-of-a-kind footwear that stands out. Whether you're painting leather sneakers, canvas shoes, or fabric footwear, these essential supplies will help you achieve professional results that last.